How to Calculate Predetermined Overhead Rate: Formula & Uses

Carefully minimizing overhead is crucial for small businesses to maintain profitability. Following expense optimization best practices and leveraging technology keeps overhead costs in check. Analyzing overhead rates by department in this manner helps identify problem areas and ledger account opportunities to improve profitability. You’ll master the key formulas, learn how to allocate costs properly across departments, see real-world examples, and discover best practices to control overhead expenses.

- Another way to view it is overhead costs are those production costs that are not categorized as direct materials or direct labor.

- It is important to include indirect costs that are based on this overhead rate in order to price a product or service appropriately.

- To account for these changes in technology and production, many organizations today have adopted an overhead allocation method known as activity-based costing (ABC).

- Larger organizations may employ a different predetermined overhead rate in each production department, which tends to improve the accuracy of overhead application by employing a higher level of precision.

- Estimating overhead costs is difficult because many costs fluctuate significantly from when the overhead allocation rate is established to when its actual application occurs during the production process.

Would you prefer to work with a financial professional remotely or in-person?

Knowing the total and component costs of the product is necessary for price setting and for measuring the efficiency and effectiveness of the organization. Remember that product costs consist of direct materials, direct labor, and manufacturing overhead. A company’s manufacturing overhead costs are all costs other than direct material, direct labor, or selling and administrative costs.

Related AccountingTools Courses

But determining the exact overhead costs is not easy, as the cost of electricity needed to dry, crush, and roast the nuts changes depending on the moisture content of the nuts upon arrival. The example shown above is known as the single predetermined overhead rate or plant-wide overhead rate. Different businesses have different ways of costing; some would use the single rate, others the multiple rates, while the rest may make use of activity-based costing. If Department B has overhead costs of $30,000 but direct costs of $70,000, then its overhead rate is 43%. Despite having lower total overhead, Department B predetermined overhead rate is less efficient since its overhead rate is higher. Businesses should understand which overhead costs are fixed vs variable when budgeting and setting overhead rates.

- Therefore, in simple terms, the POHR formula can be said to be a metric for an estimated rate of the cost of manufacturing a product over a specific period of time.

- When the $700,000 of overhead applied is divided by the estimated production of 140,000 units of the Solo product, the estimated overhead per product for the Solo product is $5.00 per unit.

- In other words, using the POHR formula gives a clearer picture of the profitability of a business and allows businesses to make more informed decisions when pricing their products or services.

- All of our content is based on objective analysis, and the opinions are our own.

- Using small business accounting software centralizes overhead tracking and analysis.

- A predetermined overhead rate is an estimated amount of overhead costs that will be incurred during a set period of time.

- As you can see, calculating your predetermined overhead rate is a crucial first step in pricing your products correctly.

Estimated Total Manufacturing Overhead Costs

- Since overhead costs cannot be easily traced to individual products like direct material or labor costs, overhead rates help to allocate a fair share of these costs based on the activity of making the product.

- Now ABC Co. can compare its estimated results with actual results to evaluate how it has performed.

- This option is best if you’re unsure of how to calculate your predetermined overhead rate or if you don’t have the time to do it yourself.

- One of the advantages of predetermined overhead rate is that it can help businesses monitor overhead rate.

- It involves estimating the manufacturing overhead costs that will be incurred over a specific period and then allocating those costs to the units produced during that period.

- However, whether ABC Co. made a profit or loss on the actual job can only be determined if the price of the job is known.

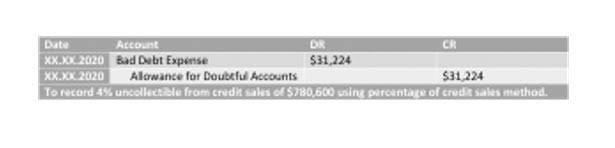

In other words, using the POHR formula gives a clearer picture of the profitability of a business and allows businesses to make more informed decisions when pricing their products or services. In this article, we will discuss the formula for predetermined overhead rate and how to calculate it. A Predetermined Overhead rate shall be used to calculate an estimate on the projects that are yet to commence for overhead costs. It would involve calculating a known cost (like Labor cost) and then applying an overhead rate (which was predetermined) to this to project an unknown cost (which is the overhead amount). The formula for calculating Predetermined Overhead Rate is represented as follows.

Finally, you would divide the indirect costs by the allocation measure to achieve how much in overhead costs for every dollar spent on direct labor for the week. While predetermined overhead rates are widely used and needed for businesses, they may have some limitations. A business needs to estimate its total overheads for a period and estimate its total units or activity basis for the predetermined overhead rates. If these estimates are not accurate, they can end up causing https://www.bookstime.com/ a lot of problems for the business specially if decisions are based on the rates, such as pricing decisions. A predetermined overhead rate is an allocation rate that is used to apply the estimated cost of manufacturing overhead to cost objects for a specific reporting period. This rate is frequently used to assist in closing the books more quickly, since it avoids the compilation of actual manufacturing overhead costs as part of the period-end closing process.

Advantages of predetermined overhead rate formula

Keeping overhead costs in check can have a notable impact on the bottom line. Optimize processes – Streamline workflows around everything from inventory to invoicing to save time and cut labor costs. This comprehensive guide breaks down overhead rate calculation into clear, actionable steps any business can follow. Then, they’ll need to estimate the amount of activity or work that will be performed in that same time period. For this example, we’ll say the marketing agency estimates that it will work 2,500 hours in the upcoming year. Conversely, the cost of the t-shirts themselves would not be considered overhead because it’s directly linked to your product (and obviously changes based on the volume of products you create and sell).